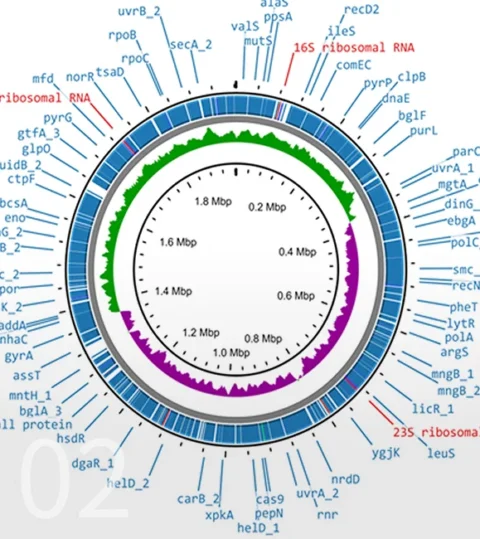

Whole-Genome Sequencing–Driven

- Decoding complete microbial genome information

- Building comprehensive fermentation metabolic models

- Predicting microbial growth characteristics

We centers on the proprietary technology platform, integrating innovative R&D and manufacturing expertise to build top-tier capabilities that enable comprehensive responses to the diverse needs of clients amid constantly evolving market and regulatory environments.

Specialized in fermentation processes, delivering high-value nutraceutical solutions across multiple platforms

Developing unique strains, bioactives, and delivery systems for better efficacy and competitiveness

Advancing sustainable fermentation technology aligned with ESG principles

Streamlining R&D to commercial-scale manufacturing with minimal risk and cost

Supporting a wide range of applications in functional F&B and supplements

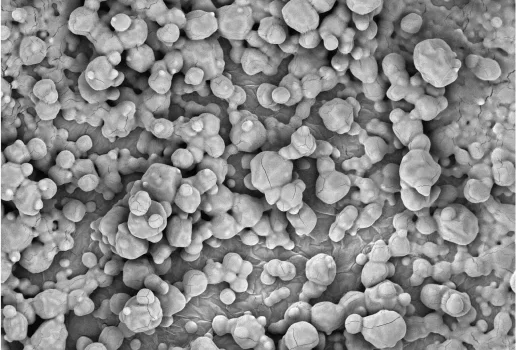

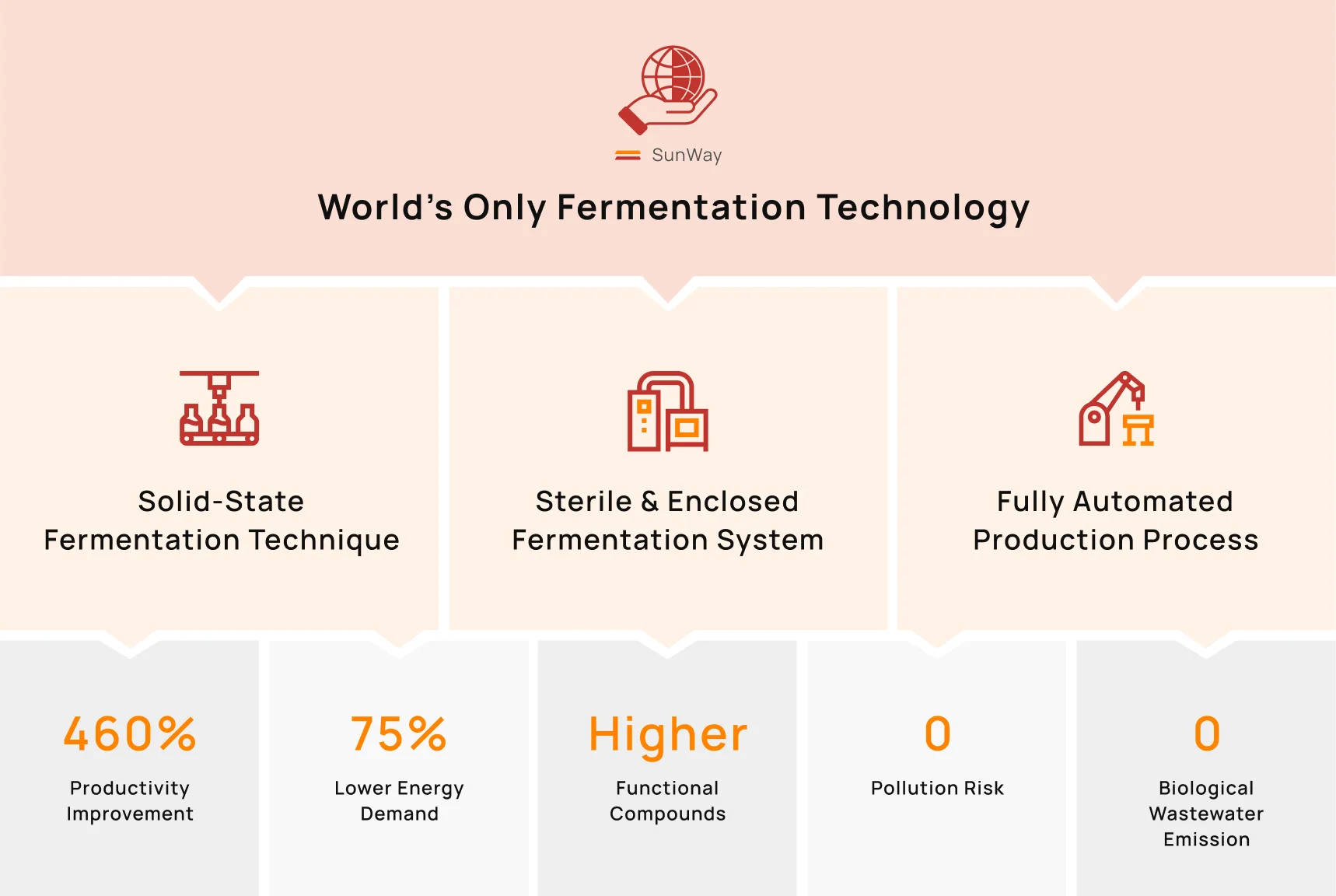

SunWay Biotech is the only red yeast rice company in the world that uses enclosed, automated solid-state fermentation. Compared with traditional fungal fermentation factories, it can be more efficient and environmentally friendly in terms of productivity and energy use.

We specialize in full-scale services for solid-state fermentation, dedicated to developing high-potency fermented ingredients for the health and wellness industry.

Our facilities are internationally certified, holding GMP, Halal, HACCP, and ISO 22000 accreditations. We are also working towards USP GMP certification to further enhance our product standards and global recognition.

ANKASCIN 568 – Successfully obtained NDI (New Dietary Ingredient) certification from the U.S. FDA.

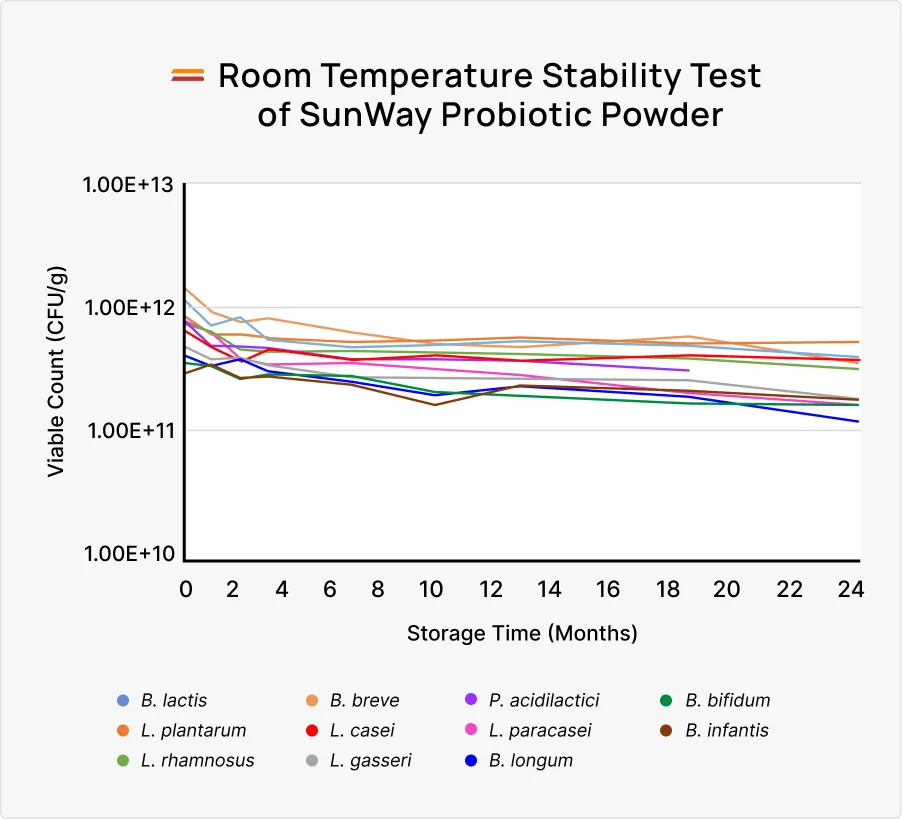

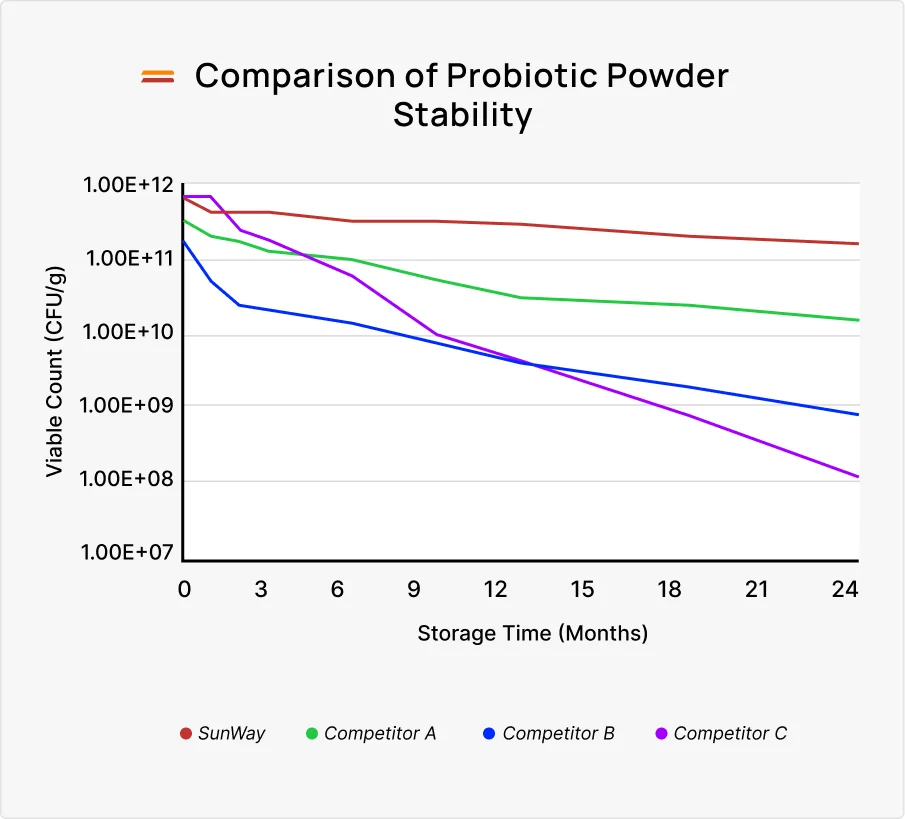

We are committed to delivering the purest and most stable liquid fermentation process. With 45 proprietary allergen-free systems, we redefine quality by exceeding bacterial count standards and ensuring long-term activity stability.

Genome-driven exclusive precision fermentation is redefining process efficiency and product quality, delivering next-generation precision biotechnology without relying on genetic modification.

Through comprehensive genome decoding and model-based design, we rapidly develop nutrient substrates and optimal growth environments tailored to microbial needs, accelerating development, building proprietary know-how, maximizing strain performance, and gaining a competitive edge in future microbial applications.

We possesses fermentation capabilities for bioactive compounds and offers comprehensive manufacturing capabilities for a wide range of functional ingredients — including red yeast rice, human and pet probiotics, next-generation probiotics, postbiotics, polysaccharides, neuro- and mental-health ingredients, proteins and peptides, exosome, as well as other emerging functional compounds.

We provide customized development and manufacturing partnership models to meet your diverse needs.

Proprietary Solid-State Fermenters and Extraction Facilities of Red Yeast Rice